Heat Transfer Fluids

Eastman offers a family of Therminol heat-stable fluids developed for indirect transfer of process heat. Therminol® heat transfer fluids meet the operating needs of virtually any single- or multiple-station heat-using system. In properly designed systems, our fluids provide excellent thermal stability in their expected temperature ranges and provide years of trouble-free service with minimal downtime.

Available in several formulations and operating ranges, Therminol provides excellent benefits, including cost and operational efficiency, minimal maintenance, and precise temperature control. Discover which Therminol fluid will work best for your application. Learn how to manage regulations and stay compliant with the right fluid—and the right experts.

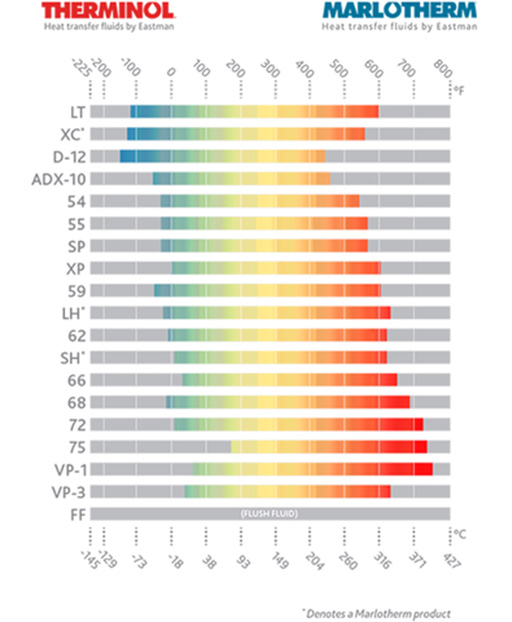

Select a heat transfer fluid from the following diagram to learn more about specific product benefits, availability, safety data, and technical specifications.

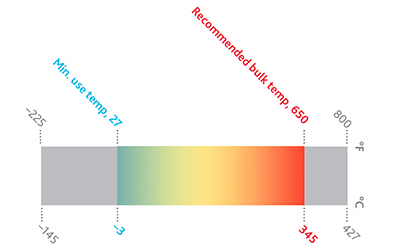

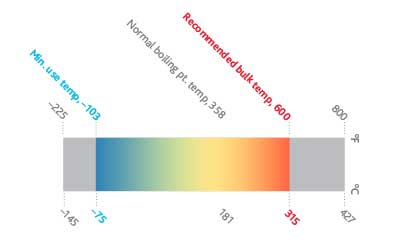

Therminol 66 is the world’s most popular high temperature, liquid-phase heat transfer fluid. Therminol 66 is pumpable at low temperatures, and offers high-temperature thermal stability.

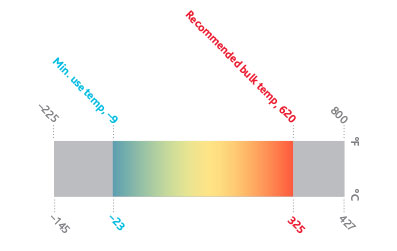

Therminol 62 is a synthetic heat transfer fluid whose chemistry is custom contoured for high-performance, high-purity, low-pressure and exceptional thermal stability.

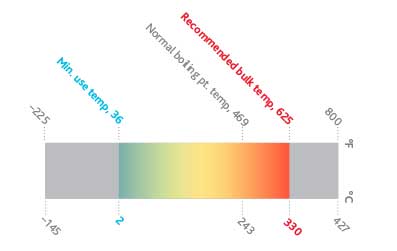

Therminol VP3 heat transfer fluid is a synthetic heat transfer fluid that was specially developed to allow vapor phase heat transfer at lower temperatures than are practical with traditional diphenyl oxide (DPO)/biphenyl constituted fluids like Therminol VP-1.

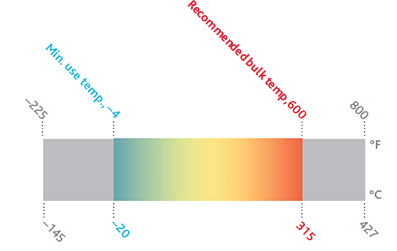

Therminol XP heat transfer fluid is an extremely pure white mineral oil which provides reliable heat transfer.

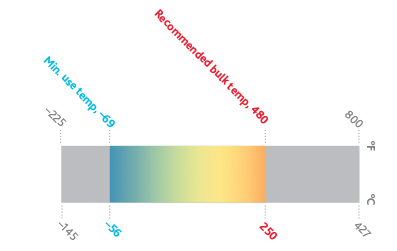

Therminol LT is a synthetic aromatic heat transfer fluid. It can be used in both liquid and vapor phase, and has excellent heat transfer and fluid properties for low-temperature applications.

Therminol D-12 is a synthetic, liquid phase heat transfer fluid with excellent heat transfer properties over a wide temperature range. This fluid is ideally suited for applications that require efficient cooling and heating.

Therminol ADX10 is a low viscosity, synthetic organic heat transfer fluid particularly recommended for indirect liquid phase process heating at medium temperatures.

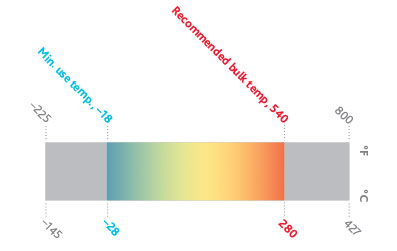

Therminol 54 is a synthetic fluid designed to provide reliable, consistent heat transfer performance over a long service life at maximum bulk temperatures up to 280°C (540°F).

Therminol SP is a synthetic heat transfer fluid used in moderate-temperature applications. Therminol SP fluid is designed for use in nonpressurized/low-pressure, indirect heating systems. It delivers efficient, dependable, uniform process heat with no need for high pressures.

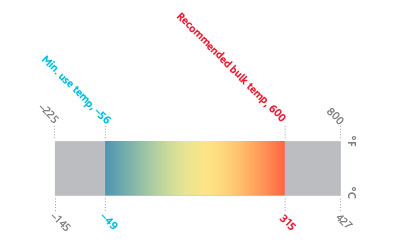

Therminol 55 is a synthetic heat transfer fluid used in moderate-temperature applications. Therminol 55 fluid is designed for use in nonpressurized/low-pressure, indirect heating systems. It delivers efficient, dependable, uniform process heat with no need for high pressures.

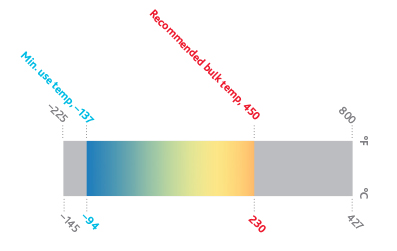

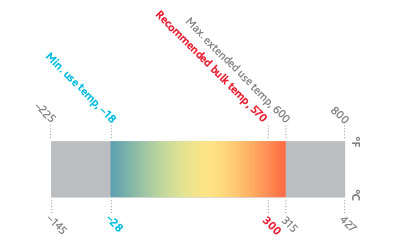

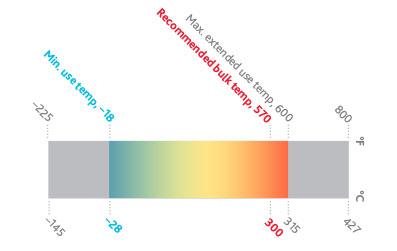

Therminol 59 is a synthetic heat transfer fluid with excellent low temperature pumping characteristics and thermal stability.

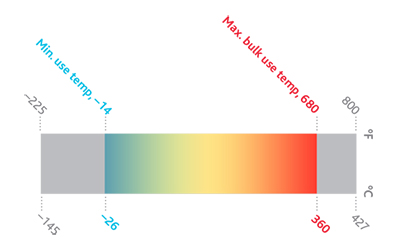

Therminol 68 is a high temperature liquid phase heat transfer fluid with excellent thermal stability. Therminol 68 was developed for use at temperatures up to 360° C (680°F) in liquid phase heat transfer fluid systems. Therminol 68 has a boiling point of 308°C (586°F), but static pressure of about 2 bar should maintain the liquid phase at high temperatures.

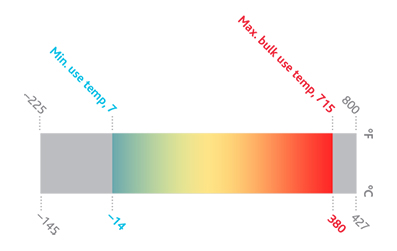

Therminol 72 is an ultra-high temperature liquid phase heat transfer fluid having excellent thermal stability. Therminol 72 was developed for use at temperatures up to 380°C (720°F) in liquid phase heat transfer systems.

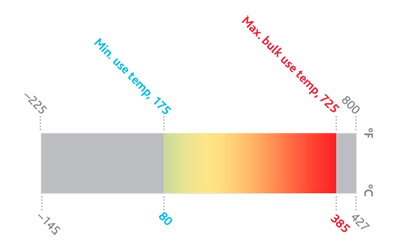

Therminol 75 synthetic heat transfer fluid is a ultra-high temperature liquid phase heat transfer fluid having excellent thermal stability.

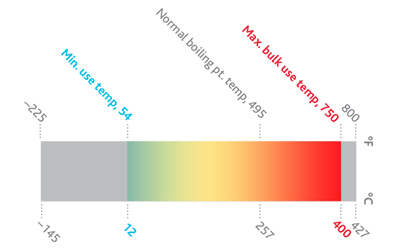

Therminol VP-1 heat transfer fluid is an ultra-high temperature synthetic heat transfer fluid designed to meet the demanding requirements of vapor phase systems or liquid phase systems.

Therminol FF is the first synthetic flushing fluid for liquid phase heat transfer systems. Deposits from oxidized, thermally degraded or contaminated fluid can foul interior surfaces, making it necessary to clean the system prior to charging with new fluid.